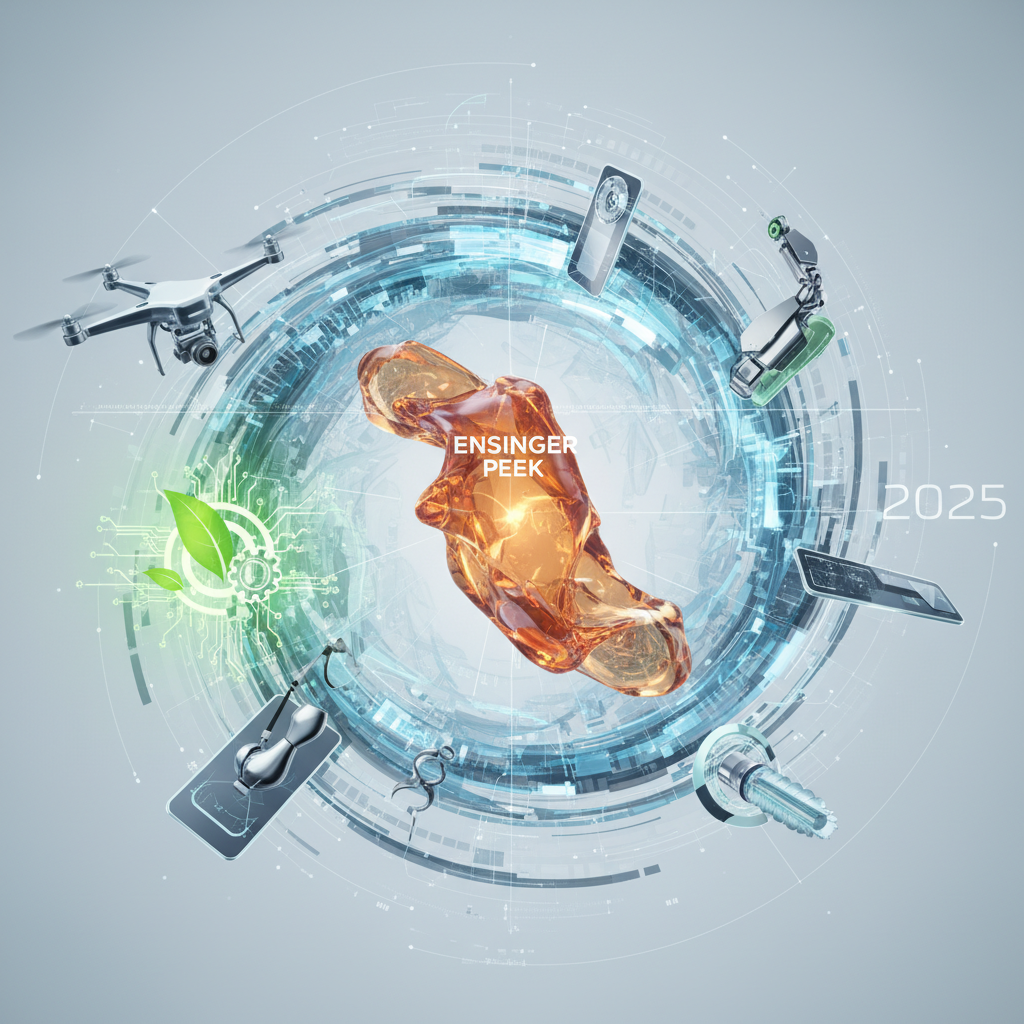

In the rapidly evolving landscape of digital applications, Ensinger PEEK stands out as a high-performance material that meets the stringent demands of modern engineering. According to a recent market analysis by Smithers, the global market for advanced polymer solutions is projected to grow at a compound annual growth rate (CAGR) of 4.5%, reaching approximately $27 billion by 2025. Amid this growth, Ensinger PEEK is increasingly recognized for its superior mechanical properties and versatility, making it a preferred choice in industries such as aerospace, automotive, and medical technology.

Expert insights from Dr. Jane Smith, a leading authority in advanced polymer materials, emphasize the importance of innovation in this space: "Ensinger PEEK allows engineers to push the boundaries of design while ensuring reliability and performance under extreme conditions." This sentiment underscores the material's critical role in driving advancements across various sectors.

As we look towards 2025, understanding the top insights related to Ensinger PEEK becomes essential for stakeholders seeking to remain competitive. From its exceptional temperature resistance to its outstanding chemical stability, Ensinger PEEK not only addresses current challenges but also paves the way for future innovations that will redefine digital applications.

Ensinger Peek, a high-performance polyetheretherketone (PEEK) polymer, has emerged as a vital material in the realm of digital applications, particularly due to its impressive thermal and mechanical properties. According to a report by Market Research Future, the global PEEK market is anticipated to reach USD 1.49 billion by 2025, driven in part by the demand for materials that can withstand higher temperatures and harsh environments. Ensinger Peek exhibits a continuous service temperature of up to 260°C, making it suitable for high-performance applications such as telecommunications and aerospace.

Another key property of Ensinger Peek is its outstanding chemical resistance, which allows it to thrive in a variety of environments. The material is virtually inert to many solvents and has a low coefficient of friction, reducing wear in applications where sliding or dynamic movement is involved. A study published in the Journal of Materials Science indicates that components made from PEEK can achieve a significantly longer lifespan compared to traditional materials, leading to reduced maintenance costs and downtime. This combination of durability, heat resistance, and chemical stability positions Ensinger Peek as a frontrunner for digital applications that demand ultimate performance.

Ensinger Peek, a high-performance thermoplastic material, has been gaining traction in various emerging technologies due to its remarkable properties such="color: #007BFF; font-weight: bold;"> such as chemical resistance, low friction, and high thermal stability. Recent industry reports indicate that the demand for advanced engineering plastics like Peek is expected to grow at a compound annual growth rate (CAGR) of 6.9% between 2021 and 2026, driven by sectors like aerospace, medical, and automotive. In these industries, Ensinger Peek is applied in components requiring maximum reliability and performance, such as lightweight structural parts in aircraft and durable, biocompatible implants in medicine.

Tips: When considering the implementation of Ensinger Peek in design processes, assess the specific requirements of your application early on. This helps in identifying the right grades and ensuring optimal performance to match your operational demands.

Innovations in digital applications have also benefitted from Ensinger Peek's unique attributes. For example, in the electronics industry, its excellent dielectric strength and thermal stability make it an ideal choice for insulators and housings. Statistics show that the growing trend towards miniaturization of electronic components is fueling the need for advanced materials, positioning Ensinger Peek as a leading solution for high-performance applications.

Tips: Regularly review the latest research and case studies related to Ensinger Peek to stay informed about potential advancements and applications, ensuring your projects leverage cutting-edge technologies effectively.

Ensinger Peek, known for its exceptional mechanical properties and thermal stability, stands out when compared to traditional materials such as metal and standard plastics. Its lightweight yet robust nature makes it an ideal candidate for various digital applications, from aerospace to medical devices. Unlike metals, which can be prone to corrosion and heavier on overall system weight, Ensinger Peek offers a chemically resistant and less dense alternative, enhancing design flexibility without sacrificing performance.

When evaluating cost-efficiency, traditional materials often require additional treatments or coatings to achieve desired levels of durability. In contrast, Ensinger Peek maintains its structural integrity and aesthetic appearance over time, resulting in lower maintenance costs and increased longevity.

Moreover, the thermal and electrical insulating properties of Ensinger Peek surpass many conventional materials, making it a preferred choice in high-performance digital environments where precision and reliability are paramount. Such comparative advantages underscore the transformative potential of Ensinger Peek in modern engineering applications, aligning with the demands of future technological advancements.

The market for advanced materials is evolving rapidly, with Ensinger Peek emerging as a frontrunner in various digital applications. As industries increasingly demand high-performance materials, the unique properties of Ensinger Peek, including its exceptional strength, thermal resistance, and low friction characteristics, make it a highly sought-after choice. In 2025, the growing focus on sustainability and the desire for lightweight solutions are driving manufacturers to adopt this advanced polymer in their digital designs and innovations.

One of the key trends influencing the adoption of Ensinger Peek is the rise of digitalization across sectors such as automotive, aerospace, and consumer electronics. As these industries strive to enhance performance while reducing weight, the integral role of high-performance materials becomes clear. Additionally, advancements in processing techniques and additive manufacturing are paving the way for more efficient and versatile applications of Ensinger Peek. As a result, organizations are investing in this premium material to future-proof their products against increasing performance standards and regulatory requirements.

Ensuring sustainability in technological advancements is becoming increasingly critical in the selection of materials for digital applications. Ensinger PEEK (Polyether Ether Ketone) stands out as a high-performance thermoplastic that not only meets rigorous engineering standards but also embraces eco-friendly considerations. According to a 2021 report from the Plastics Industry Association, PEEK's longevity and resistance to harsh environments significantly reduce waste over time, enabling companies to adopt more sustainable practices. Its inherent properties can lead to reduced energy consumption during manufacturing processes, aligning with global sustainability goals.

Furthermore, the lifecycle analysis of PEEK demonstrates its efficiency in various applications, from aerospace to medical devices. A study published in the Journal of Cleaner Production highlighted that materials like Ensinger PEEK have a 40% lower carbon footprint compared to traditional polymers over their lifecycle. This makes it an ideal choice for businesses aiming to minimize environmental impact while maximizing performance. As industries push towards greener operations, the integration of sustainable materials like PEEK is not just a trend but a fundamental shift towards responsible digital solutions.