In the ever-evolving world of materials science, understanding "peek mechanical properties" is crucial. Dr. Emily Zhang, a leading expert in polymer engineering, emphasizes, "The true potential of PEEK lies in its mechanical robustness." This statement underlines the importance of analyzing mechanical properties for various applications.

PEEK, or polyether ether ketone, is known for its strength and durability. Its mechanical properties, such as tensile strength and thermal stability, are vital. For engineers, dissecting these characteristics can lead to better project outcomes. However, common mistakes often occur during analysis, such as overlooking the impact of temperature on performance.

It's essential to approach "peek mechanical properties" with a critical mindset. Data can be misleading if not interpreted correctly. In a rapidly changing industry, continuous learning and adaptation are keys. Embracing the complexity of PEEK will ensure your projects succeed.

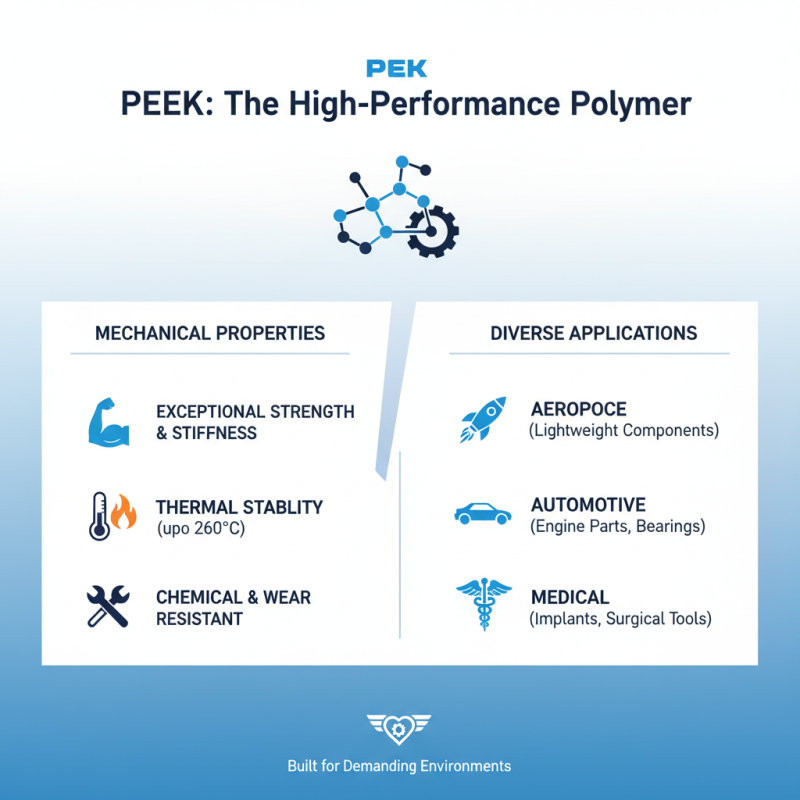

Understanding the mechanical properties of PEEK is essential for many projects. PEEK, known for its strength and thermal stability, finds applications in diverse fields. These include aerospace, automotive, and medical sectors. Its unique characteristics make it suitable for demanding environments.

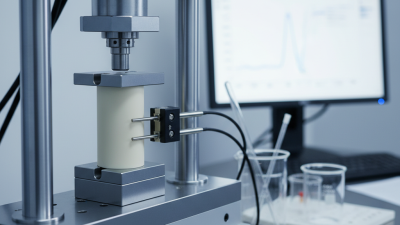

When analyzing PEEK, focus on tensile strength, modulus of elasticity, and impact resistance. These properties indicate how PEEK will perform under stress. Tensile strength determines the maximum load before failure. A high modulus indicates stiffness, reflecting how PEEK will bend or compress.

Consider the challenges when measuring these properties. Factors like temperature and humidity can affect results. Testing under different conditions is crucial, yet it can lead to variations. Real-world application often presents complexities, which might not align with lab results. This disparity requires careful interpretation and adjustment in project designs.

When analyzing peak mechanical properties, it’s crucial to focus on key factors that influence performance. PEEK, or polyether ether ketone, is recognized for its exceptional strength and stability. However, several aspects impact its mechanical performance. Temperature resistance is one vital factor. Reports indicate that PEEK can maintain up to 90% of its strength at elevated temperatures.

Another factor is the manufacturing process. How PEEK is processed can significantly alter its properties. For instance, injection molding often yields different results than extrusion. Proper processing conditions are necessary to avoid defects, which can weaken the material. The molecular weight of PEEK also plays a role; higher molecular weights typically provide improved tensile strength.

Tips: Regularly review data on the specific applications of PEEK. Consult recent industry studies to identify any emerging trends. Additionally, monitor how variations in processing impact the final product’s performance. This helps in making informed decisions during project development.

The environment in which PEEK is used can’t be overlooked. Exposure to chemicals and moisture may degrade performance. While PEEK is chemically resistant, it’s still wise to test its compatibility with your specific applications. Some tests may reveal unexpected weaknesses. Reflecting on these aspects during analysis is essential for success.

This chart represents the mechanical properties of PEEK (Polyether ether ketone) at varying temperatures, showcasing its tensile strength and modulus of elasticity. The data illustrates how these properties change with temperature, which is critical for engineering applications.

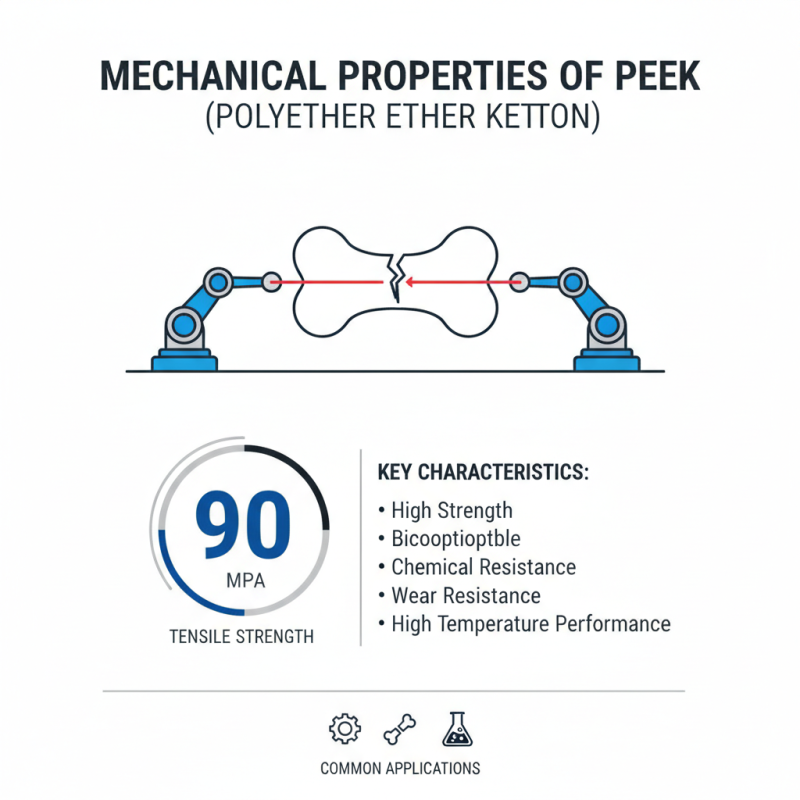

When analyzing the mechanical properties of PEEK (polyether ether ketone), several testing methods can be employed. One popular approach is tensile testing, which measures how much a material can stretch before breaking. According to industry reports, PEEK typically exhibits a tensile strength of around 90 MPa. This property makes it suitable for various engineering applications.

Another effective method is impact testing. This assesses a material's resistance to sudden forces. PEEK shows impressive toughness, often scoring above 15 kJ/m² on the Charpy test. This metric is crucial when considering the material for components in environments that experience vibrations or shocks.

Tips: Always ensure that your samples are properly prepared. Uneven surfaces can lead to inaccurate results. For accurate data, run multiple tests and calculate an average. Do not overlook environmental factors, such as temperature and humidity, which can affect your readings.

Whenever testing PEEK, keep in mind the need for consistency. Even minor deviations in test settings can produce varying results. This inconsistency might lead to misjudgments in material selection for critical projects. It's essential to analyze these parameters thoroughly to ensure reliable outcomes.

Analyzing mechanical properties of PEEK is crucial for various projects. Understanding test results can guide material selection. When interpreting data, one should focus on tensile strength, elongation, and flexural modulus. These parameters reflect how PEEK behaves under stress.

The tensile strength indicates how much force PEEK can withstand. A high value means better performance in demanding applications. Elongation measures the plastic deformation before breaking. A lower percentage can suggest brittleness, which requires careful consideration. The flexural modulus, on the other hand, shows stiffness. Projects needing flexibility may not perform well with high stiffness materials.

Data might present unexpected results. Sometimes, tests reveal lower properties than anticipated. This should prompt reviewers to rethink methodologies. Are the test conditions representative? Did the sample preparation play a role? Reflecting on these questions is essential. Understanding the context of the results aids informed decisions. This makes the analysis not just about numbers, but practical implications in design.

| Test Parameter | Value | Units | Comments |

|---|---|---|---|

| Tensile Strength | 100 | MPa | Typical value for PEEK |

| Flexural Modulus | 3600 | MPa | High stiffness |

| Thermal Decomposition Temp | 550 | °C | Good heat resistance |

| Elongation at Break | 40 | % | Indicates ductility |

| Impact Strength | 6 | kJ/m² | Resistance to impact |

PEEK, or polyether ether ketone, is gaining traction in various industrial applications. Its excellent mechanical properties make it an appealing option. This high-performance thermoplastic shines in fields like aerospace, automotive, and medical devices. Each application demands specific property requirements. For instance, aerospace components require lightweight materials that can withstand high temperatures.

In automotive projects, PEEK is favored for its resistance to chemicals and wear. It maintains structural integrity under constant stress. Medical applications necessitate biocompatibility and sterilization resistance. PEEK meets these needs, often replacing metal parts. However, understanding its limitations is crucial. While PEEK excels in many areas, it can be expensive and challenging to process.

Different projects may require different analyses. Mechanical properties such as tensile strength, impact resistance, and thermal stability need evaluation. Engineers face challenges when balancing these properties with production costs. This necessitates careful consideration and trial runs. PEEK's versatility is undoubted, but it requires thoughtful application to yield the best outcomes. Exploring these aspects can lead to more efficient project development.