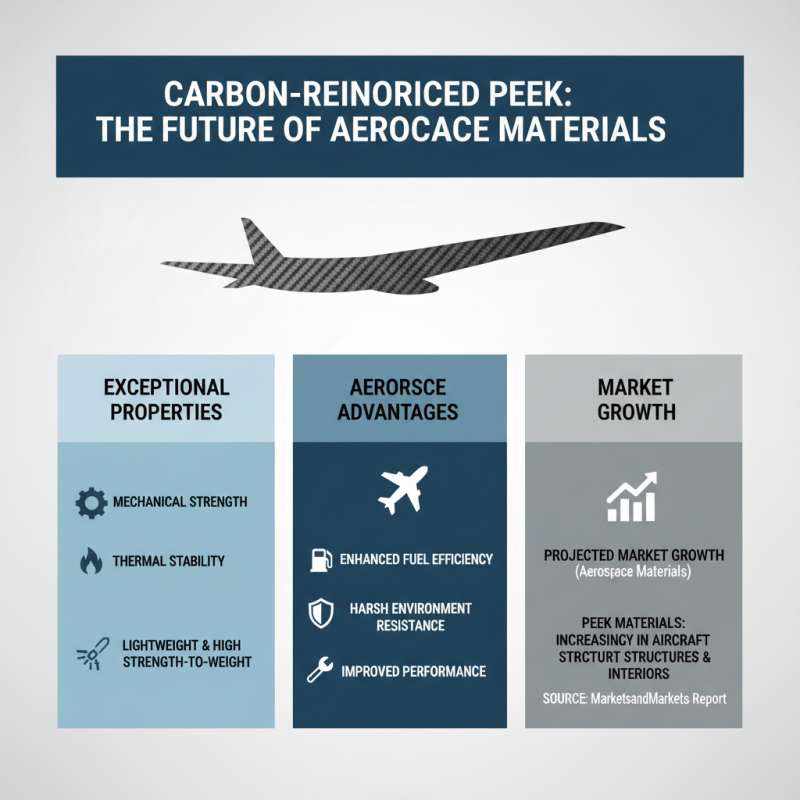

In recent years, the demand for advanced materials in various industries has led to significant innovations, particularly in the realm of polymers. Among these developments, carbon reinforced PEEK (Polyether ether ketone) has emerged as a formidable contender due to its exceptional mechanical properties and versatility. According to a report by MarketsandMarkets, the global PEEK market is projected to reach USD 1.2 billion by 2025, driven by the material’s performance in extreme conditions and its growing application in aerospace, automotive, and medical sectors. The integration of carbon fibers into PEEK enhances its strength-to-weight ratio, making it an ideal choice for applications where lightweight and durability are paramount.

The advantages of carbon reinforced PEEK extend beyond mere strength; it also offers improved thermal stability and chemical resistance, making it suitable for high-performance applications. A study published in the Journal of Materials Science highlights that the addition of carbon fibers can lead to a significant increase in tensile strength and modulus, thus allowing manufacturers to reduce component weight while maintaining structural integrity. As industries continue to seek sustainable and high-performing materials, carbon reinforced PEEK stands out as a solution that not only meets but exceeds the stringent requirements of modern engineering. This article delves into the top 10 benefits of carbon reinforced PEEK that professionals and decision-makers need to consider when selecting materials for their next project.

Carbon reinforced PEEK (Polyether Ether Ketone) has emerged as a game-changer for high-temperature applications due to its exceptional thermal stability and mechanical strength. This advanced material boasts a continuous operating temperature of up to 250°C, making it ideal for industries such as aerospace, automotive, and medical, where components must endure extreme heat without compromising performance. The carbon reinforcement enhances the structural integrity of PEEK, allowing it to retain its shape and strength, even under intense thermal stress.

When working with carbon reinforced PEEK, it's essential to consider the specific requirements of your application. Tips for optimizing performance include ensuring proper machining techniques, as its toughness can require specialized tools that maintain sharpness. Additionally, combining carbon reinforced PEEK with efficient cooling systems can help manage temperatures effectively during operations, prolonging the lifespan of the components.

Another factor to bear in mind is the compatibility of carbon reinforced PEEK with various fluids and chemicals. This material exhibits excellent resistance to a wide array of substances, making it suitable for challenging environments. However, always conduct thorough testing to ensure that it meets the needs of your specific application, providing both performance reliability and durability in high-temperature settings.

This chart illustrates the top 10 benefits of Carbon Reinforced PEEK, showcasing its performance in high-temperature applications.

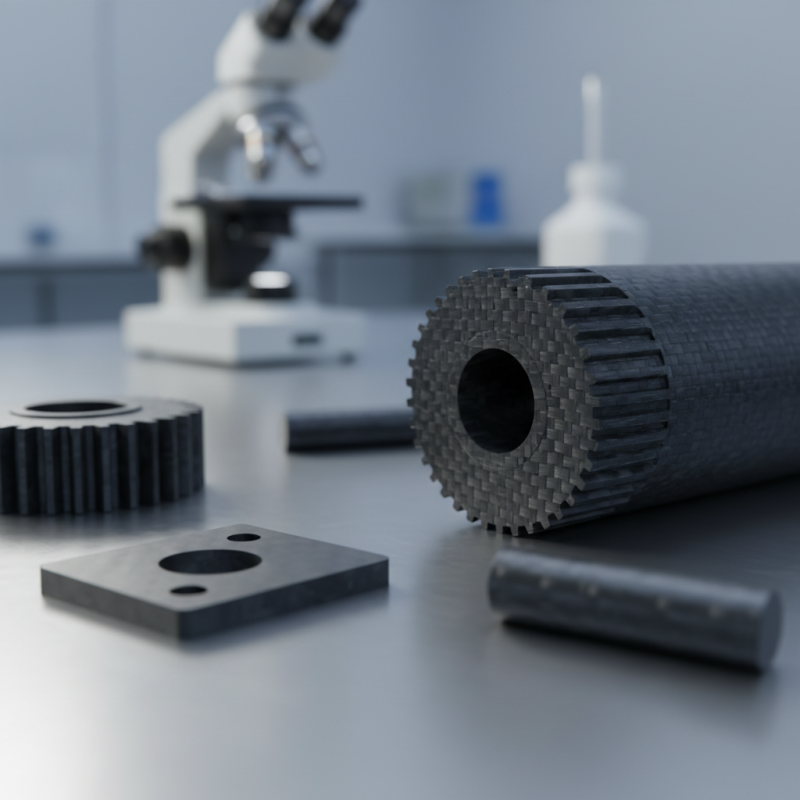

Carbon reinforced PEEK (Polyetheretherketone) has emerged as a superior material in various engineering applications, primarily due to its enhanced mechanical properties. The incorporation of carbon fibers significantly increases the tensile strength and stiffness of PEEK, making it an attractive choice for industries that demand materials capable of withstanding high stress and extreme conditions. This reinforcement not only improves the load-bearing capacity of PEEK but also enhances its dimensional stability, reducing the likelihood of deformation under operational loads.

Moreover, carbon reinforced PEEK exhibits excellent fatigue resistance, which is essential in dynamic applications where materials are subjected to repetitive stress. The durability afforded by this composite material allows it to maintain integrity and performance over extended periods, minimizing the need for frequent repairs or replacements. Additionally, the lightweight nature of carbon reinforced PEEK contributes to overall efficiency in design, particularly in sectors such as aerospace and automotive, where reducing weight while maintaining strength is a critical consideration.

Overall, the enhanced mechanical properties of carbon reinforced PEEK make it a pivotal material for advanced engineering solutions.

Carbon reinforced polyether ether ketone (PEEK) is increasingly recognized for its exceptional chemical resistance properties, making it an ideal choice for various industrial applications. According to a study by the International Journal of Polymer Science, PEEK exhibits remarkable resistance to a wide array of chemicals, including acids, bases, and organic solvents. This resilience is crucial in environments where materials are frequently exposed to aggressive substances, as it significantly reduces the risk of degradation and failure.

Furthermore, comparative analyses demonstrate that carbon reinforced PEEK outperforms many traditional materials in terms of chemical stability. A report by the Engineering Plastics Conference noted that PEEK maintains its mechanical integrity and performance characteristics even when subjected to harsh chemical environments at elevated temperatures. The material's resistance to stress cracking in the presence of certain solvents further enhances its reliability in demanding applications, such as aerospace, automotive, and medical industries, where safety and durability are paramount. The growing adoption of carbon reinforced PEEK can be attributed to these chemical resistance advantages, ultimately leading to reduced maintenance costs and extended service life of components.

Carbon reinforced Polyether Ether Ketone (PEEK) is making waves in various industries due to its impressive lightweight and durable properties. The combination of carbon fibers with PEEK significantly enhances the mechanical strength and stiffness of the material, making it an ideal choice for applications where both weight reduction and structural integrity are critical. According to a report by Grand View Research, the global carbon fiber reinforced polymer market is expected to reach USD 60.25 billion by 2025, indicating a growing preference for lightweight, high-performance materials. This trend emphasizes the need for alternative solutions like carbon reinforced PEEK that not only meet stringent performance criteria but also contribute to sustainability through their lightweight characteristics.

The role of carbon reinforced PEEK extends beyond mere lightweighting; it provides superior resistance to chemicals and high temperatures, making it suitable for harsh environments. The material boasts a thermal stability rating up to 300°C, which is crucial for aerospace and automotive applications that require reliable performance under extreme conditions. According to a study conducted by the Journal of Composite Materials, carbon fiber reinforcement can improve the tensile strength of PEEK by up to 60%. This remarkable enhancement translates into significant benefits for industries aiming to optimize performance while managing weight, ultimately leading to more efficient and effective designs in manufacturing and engineering sectors.

Carbon reinforced PEEK (Polyether Ether Ketone) has gained considerable traction across various industries due to its exceptional mechanical properties and thermal stability. In the aerospace sector, for instance, the lightweight and strength-to-weight ratio of carbon reinforced PEEK is leveraged to manufacture components that can withstand harsh environmental conditions, resulting in enhanced fuel efficiency. According to a report by MarketsandMarkets, the aerospace materials market is projected to grow significantly, with PEEK materials being increasingly incorporated into aircraft structures and interior components, contributing to weight reduction and improved performance.

In the medical field, carbon reinforced PEEK is becoming a preferred material for implants and surgical instruments. Its biocompatibility and radiolucency allow for better imaging during diagnostic procedures, leading to improved patient outcomes. A study published in the Journal of Biomedical Materials Research indicated that PEEK composites exhibit superior mechanical properties compared to traditional materials, leading to higher durability and longevity of implants. This transformation in medical technology underscores the growing potential of carbon reinforced PEEK in advancing patient care while also driving innovation in orthopedic and dental applications.

Additionally, the automotive industry is embracing carbon reinforced PEEK for manufacturing high-performance components. With the global push for lighter and more efficient vehicles, engineers are turning to advanced composites to reduce weight without sacrificing strength. The International Council on Clean Transportation reported that materials like carbon reinforced PEEK could reduce vehicle weight by up to 30%, significantly lowering carbon emissions. This trend not only aligns with environmental regulations but also enhances vehicle performance, making carbon reinforced PEEK a go-to solution across diverse technological realms.