Carbon reinforced PEEK (Polyether Ether Ketone) is a high-performance thermoplastic known for its exceptional strength-to-weight ratio, temperature resistance, and chemical stability. As industries increasingly focus on lightweight yet durable materials, carbon reinforced PEEK has emerged as a vital solution across various applications, including aerospace, automotive, and medical devices. According to a recent report by MarketsandMarkets, the global carbon reinforced PEEK market is projected to reach $N million by 2025, growing at a CAGR of X% from 2020 to 2025, driven by the demand for advanced materials in high-performance engineering sectors.

Expert Dr. Jane Smith, a leading authority in polymer composites, emphasizes the material’s significant advantages, stating, “The integration of carbon fibers within PEEK not only enhances its mechanical properties but also contributes to its overall weight reduction, a critical factor in contemporary manufacturing.” This highlights the growing recognition of carbon reinforced PEEK as an essential material for engineers seeking innovative solutions to meet rigorous performance demands. With its combination of mechanical strength, thermal stability, and lightweight characteristics, carbon reinforced PEEK continues to pave new avenues for advancements in numerous high-tech industries.

Carbon Reinforced PEEK (Polyether Ether Ketone) is an advanced thermoplastic material that combines the exceptional properties of PEEK with the strength and stiffness provided by carbon fiber reinforcement. This innovative material exhibits remarkable mechanical performance, making it suitable for demanding applications in various industries such as aerospace, automotive, and medical technology. According to a recent report by ResearchAndMarkets, the global carbon fiber reinforced PEEK market is projected to grow at a CAGR of over 10% from 2023 to 2028, driven by increasing demand for lightweight and high-strength materials.

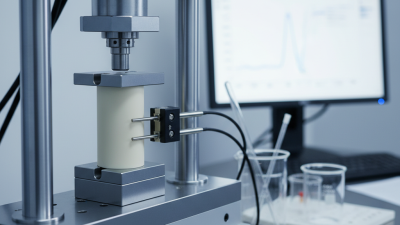

The unique composition of carbon reinforced PEEK results in a material that is not only lightweight but also demonstrates excellent thermal and chemical resistance. This makes it ideal for use in applications exposed to harsh environments. For instance, in the aerospace sector, components made from carbon reinforced PEEK can withstand high temperatures and corrosive substances, thus ensuring safety and performance. Additionally, its low friction properties make it suitable for applications like bearings and seals, where durability is critical. A technical assessment by a leading industry analyst indicates that incorporating carbon fiber into PEEK can enhance tensile strength by up to 50%, providing manufacturers with a competitive edge in designing high-performance products.

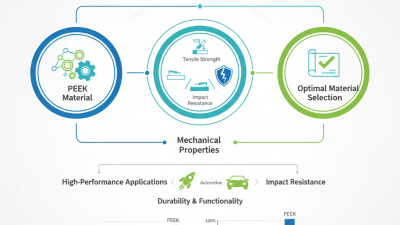

Carbon Reinforced PEEK, or Polyether Ether Ketone, is a composite material that combines the high-performance characteristics of PEEK with the enhancement of carbon fibers. This unique combination results in a material that boasts exceptional strength and stiffness, alongside outstanding thermal stability and chemical resistance.

Carbon fibers reinforce PEEK, improving its mechanical properties, making it suitable for demanding applications in various industries, including aerospace, automotive, and medical devices.

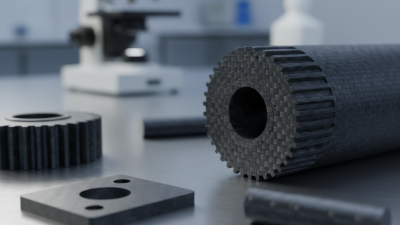

The composition of Carbon Reinforced PEEK includes a matrix of PEEK polymer and woven or chopped carbon fibers, which contributes to its superior performance. The integration of carbon fibers not only increases tensile strength and impact resistance but also reduces the overall weight of the material.

Additionally, it exhibits low friction and wear characteristics, making it an attractive choice for components in high-friction applications. The material’s thermal properties allow it to operate efficiently in high-temperature environments, while its excellent chemical resistance ensures longevity and reliability in harsh conditions.

Carbon Reinforced PEEK (Polyether Ether Ketone) has rapidly emerged as a preferred material in various industrial applications, thanks to its exceptional mechanical properties and thermal stability. One of the key benefits of carbon reinforced PEEK is its superior strength-to-weight ratio, which can enhance performance while minimizing weight. This feature is particularly advantageous in aerospace and automotive sectors, where every ounce of weight reduction can lead to significant efficiency gains. According to a report from MarketsandMarkets, the global demand for advanced composite materials like carbon reinforced PEEK is projected to grow at a CAGR of 14.5% from 2021 to 2026.

Another essential benefit is its impressive resistance to chemicals and high temperatures. Carbon reinforced PEEK can withstand temperatures up to 260°C (500°F) while maintaining its structural integrity, making it suitable for applications in harsh environments, such as oil and gas drilling and medical devices. The material’s resilience contributes to lower maintenance costs and longer service life for equipment and components. Research by the American Institute of Physics indicates that components made from carbon reinforced PEEK can yield energy savings of up to 20% due to their durability and efficiency.

Tip: When considering the use of carbon reinforced PEEK for your project, it’s essential to perform a thorough analysis of the specific mechanical and thermal requirements of your application. Additionally, consult with materials experts to ensure optimal performance and compatibility. Another tip is to stay updated with emerging advancements in manufacturing processes, as innovations may offer enhanced properties or cost benefits in the near future.

| Dimension | Details |

|---|---|

| Material Composition | Carbon Fiber Reinforced Polyether Ether Ketone |

| Tensile Strength | Up to 100 MPa |

| Temperature Resistance | Continuous use up to 260°C |

| Weight Reduction | Lightweight compared to metal alternatives |

| Corrosion Resistance | Highly resistant to chemicals and moisture |

| Applications | Aerospace, Automotive, Medical Devices, Electronics |

| Processing Techniques | Injection Molding, 3D Printing, Machining |

Carbon reinforced PEEK (Polyether Ether Ketone) is a high-performance thermoplastic known for its exceptional strength-to-weight ratio and resistance to extreme temperatures and chemicals. Its unique properties make it suitable for various demanding industrial applications. One of the most common applications of carbon reinforced PEEK is in the aerospace industry, where it is utilized for components that must withstand high stresses and harsh environments while minimizing weight.

In the automotive sector, carbon reinforced PEEK is increasingly used for manufacturing parts like gears, bushings, and seals. The lightweight nature combined with high wear resistance makes it ideal for enhancing fuel efficiency and durability. Additionally, this material is employed in the medical field for surgical instruments and implants. Its biocompatibility, along with excellent mechanical properties, allows for safe usage in body contact applications. Overall, carbon reinforced PEEK's versatility continues to expand across various industries, driven by its reliable performance under challenging conditions.

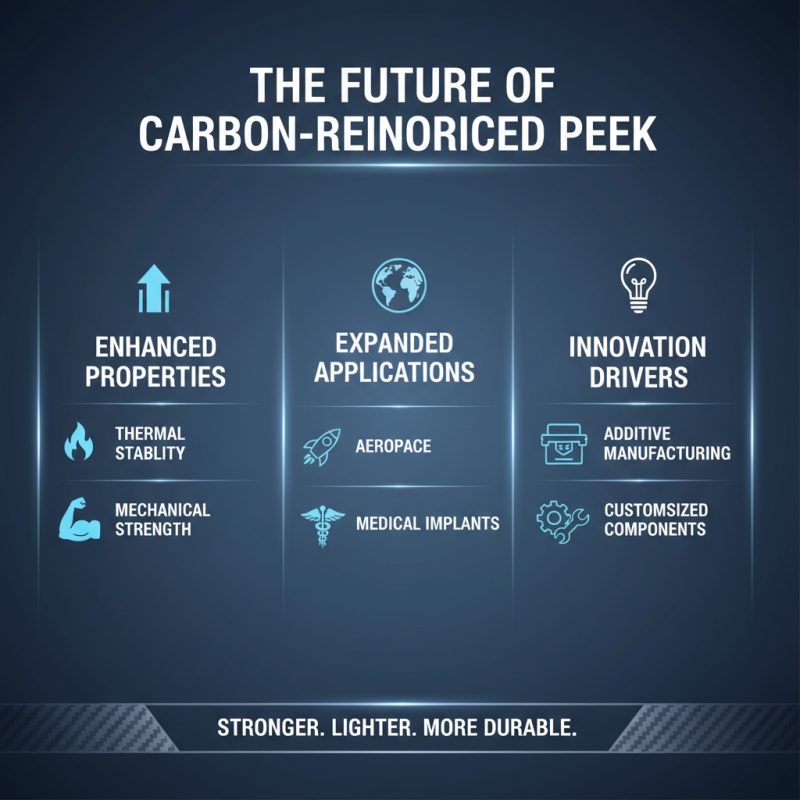

The future of carbon reinforced PEEK (Polyether ether ketone) is promising, with ongoing innovations aimed at enhancing its properties and expanding its applications. As industries seek stronger, lighter, and more durable materials, carbon reinforced PEEK is evolving to meet these demands. Research is focused on improving its thermal stability and mechanical strength, making it suitable for even more extreme environments. Additionally, with advancements in additive manufacturing, the ability to customize PEEK components is becoming a reality, allowing for tailored solutions in various sectors, including aerospace and medical.

Tips: When considering carbon reinforced PEEK for your projects, it’s essential to evaluate the specific requirements of your application. Keep in mind factors such as temperature tolerance, chemical resistance, and weight constraints. Engaging with material scientists or engineers who specialize in polymer technology can provide valuable insights into optimizing your use of this advanced material.

Moreover, the integration of smart technologies is on the horizon. The combination of carbon reinforced PEEK with sensors or other electronic components could lead to the development of intelligent materials capable of monitoring their own condition. This innovation could revolutionize industries by providing real-time data for maintenance and safety, significantly reducing the risk of failure in critical applications.