Peek CF30 is a high-performance polymer known for its exceptional material properties. In the words of Dr. Emily Carter, a leading expert in advanced materials, "The unique composition of Peek CF30 allows for unmatched strength and thermal stability." This is especially important in applications that demand durability under extreme conditions.

The peek cf30 material properties make it ideal for aerospace, automotive, and medical applications. This polymer can withstand high temperatures while maintaining its structural integrity. Its chemical resistance further enhances its versatility, making it a preferred choice in diverse industries.

However, it is crucial to understand that not all applications may find Peek CF30 suitable. The cost of this high-performance material can be a barrier for some projects. Additionally, its machining can present challenges, as precise handling is required. Awareness of these limitations is essential for effective utilization.

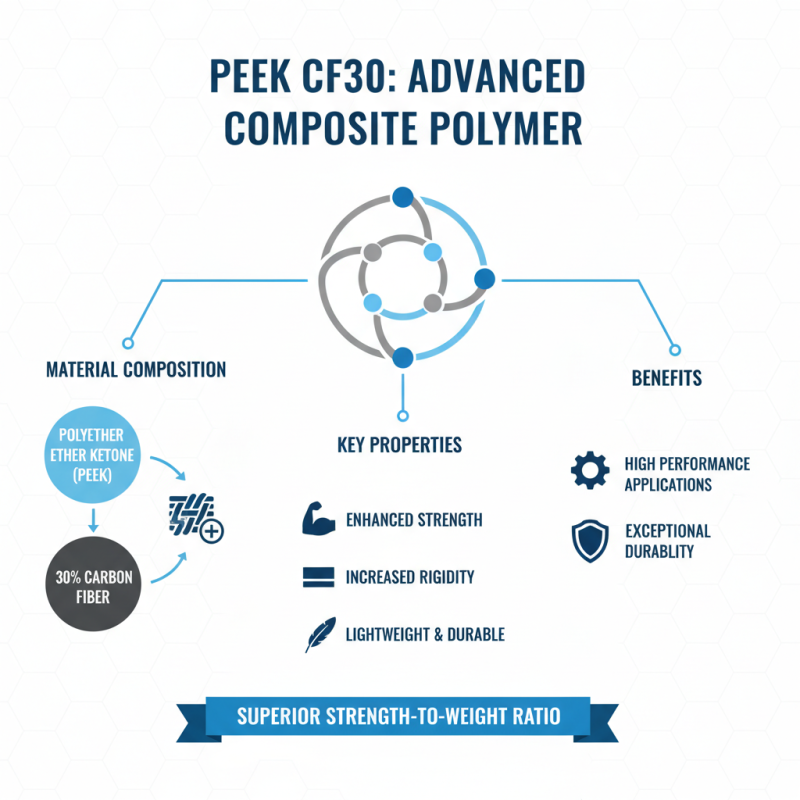

PEEK CF30 is a specialized polymer known for its unique material composition. It combines polyether ether ketone (PEEK) with 30 percent carbon fiber. This blend significantly enhances its mechanical properties. The carbon fibers provide added strength and rigidity. The result is a lightweight material that doesn't compromise on durability.

One notable aspect of PEEK CF30 is its resistance to extreme temperatures. It performs well in harsh environments, making it suitable for various applications. However, processing this material can be tricky. It often requires specialized machinery and techniques. The carbon fiber can be difficult to mold and may not behave like traditional polymers during manufacturing.

In terms of chemical resistance, PEEK CF30 stands out. It withstands a wide range of aggressive chemicals. That said, its surface can be challenging to bond with adhesives. This aspect requires careful consideration in design and application. The unique properties of PEEK CF30 make it an attractive option, but they also call for deeper understanding and proper handling.

PEEK CF30 is a variant of PEEK known for its enhanced thermal properties. This material can withstand high temperatures without degradation. Its thermal stability is impressive, maintaining structural integrity at temperatures up to 260°C. This makes it suitable for demanding applications.

The thermal conductivity of PEEK CF30 is relatively low, around 0.25 W/mK. This characteristic helps in thermal insulation, but it might also pose challenges in certain designs. Effective heat dissipation is crucial, especially in high-performance environments. Engineers need to consider this when selecting materials.

Additionally, PEEK CF30 exhibits a high glass transition temperature of about 143°C. This allows it to retain strength and rigidity under heat. However, the challenges of processing and molding this material can be significant. Some forms may require special techniques. Not all applications may benefit from its high-temperature performance, raising questions about suitability.

PEEK CF30 is an advanced composite material. Its mechanical strength is one of its most appealing features. This material exhibits impressive tensile strength, making it suitable for heavy-duty applications. The carbon fibers in CF30 enhance its rigidity and reduce the risk of deformation under stress.

The material also performs well in extreme temperatures. It maintains its strength and dimensional stability even when exposed to heat. However, one must consider challenges in machining and processing. The high strength can make cutting and forming difficult. These factors demand careful planning in manufacturing processes.

Another aspect is its fatigue resistance. PEEK CF30 can withstand repeated loads without significant wear. This is crucial for parts in dynamic environments. Nevertheless, continuous use can lead to unexpected failures. Therefore, regular inspection and maintenance are essential. Achieving an optimal performance with PEEK CF30 requires understanding its limitations and strengths.

PEEK CF30 exhibits impressive chemical resistance, making it suitable for harsh environments. This material can withstand many aggressive substances, including organic solvents and strong acids. Its unique composition allows for stability during prolonged exposure. However, it does have limitations. Some concentrated acids may still cause degradation over time.

When considering PEEK CF30 for applications, one must evaluate the specific chemicals it will encounter. Some environments may expose the material to unexpected interactions. Careful assessment is essential to ensure optimal performance. Inadequate testing might lead to failures in critical applications. The resilience of PEEK CF30 is remarkable; however, understanding its chemical resistance thoroughly is necessary.

Providing adequate protection against corrosive agents is crucial. While PEEK CF30 can endure various conditions, caution is always warranted. Regular maintenance can help identify potential material fatigue. Additionally, proper storage is important to prevent premature failure. Balancing its strengths and vulnerabilities can lead to successful applications in demanding settings.

PEEK CF30 is a specialized material known for its unique properties. Its carbon fiber reinforcement enhances strength and rigidity. This makes it suitable for demanding applications in various industries. The addition of 30% carbon fiber significantly increases its mechanical capabilities. Many reports highlight PEEK CF30's impressive tensile strength of around 95 MPa. This strength allows it to withstand high-stress environments.

One common application involves parts in the aerospace sector. PEEK CF30 is used for components that require lightweight yet durable materials. In automotive industries, it finds use in parts that endure extreme temperatures and pressures. The material's excellent resistance to chemicals and heat reinforces its position. According to studies, its thermal stability remains effective up to 260°C.

Despite its advantages, some users note the processing difficulty. Molding and machining can be challenging for some manufacturers. This requires advanced techniques and understanding of the material. Companies need to invest in proper training for their teams. Factors like cost also present a barrier for widespread adoption. Balancing benefits with these challenges is crucial for successful implementation.