In recent years, the demand for high-performance materials has surged across various industries, with peek polymer emerging as a leading contender in this evolving landscape. Renowned materials scientist Dr. Emily Carter, an expert in polymer synthesis, has emphasized the transformative potential of peek polymer, stating, "The unique combination of strength, thermal resistance, and chemical stability found in peek polymer makes it an unparalleled choice for today's high-performance applications." This statement encapsulates why peek polymer is being heralded as the future of advanced materials.

Peek polymer stands out due to its exceptional properties, including its ability to withstand extreme temperatures and aggressive chemicals, making it ideal for use in aerospace, automotive, and medical sectors. As industries continue to push the boundaries of performance and efficiency, the versatility and reliability of peek polymer position it as a vital material for innovation. This introduction sets the stage for a deeper exploration of how peek polymer not only addresses current challenges but also paves the way for future advancements in high-performance applications.

PEEK polymer, known for its exceptional thermal and chemical resistance, is quickly emerging as a leader in high-performance materials. Its ability to withstand extreme temperatures, often exceeding 250°C, makes it ideal for applications in industries such as aerospace, automotive, and medical devices. This thermal stability ensures that PEEK maintains its structural integrity even under prolonged exposure to harsh conditions, which is critical in environments where reliability is paramount.

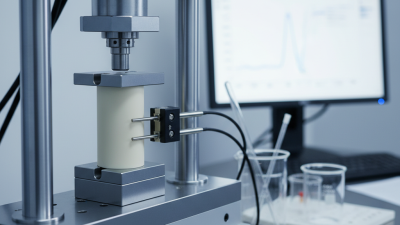

Additionally, PEEK's unique mechanical properties contribute to its growing popularity. It possesses high tensile strength and rigidity, ensuring durability and longevity in components subjected to significant stress. Furthermore, this polymer is inherently resistant to wear and abrasion, which minimizes maintenance needs and enhances overall efficiency in applications ranging from gears to seals. The low friction coefficient of PEEK also reduces energy consumption, making it a smart choice for various engineering solutions that demand both performance and sustainability.

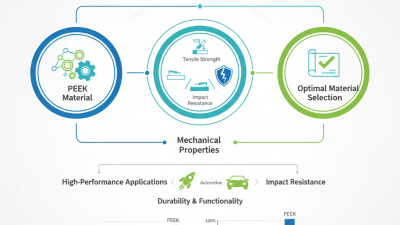

PEEK (Polyether Ether Ketone) polymer stands out in the realm of high-performance materials due to its exceptional properties, which often surpass those of traditional alternatives like PTFE and POM. For instance, PEEK boasts a continuous service temperature of up to 260°C, making it suitable for demanding applications in aerospace and automotive sectors where thermal stability and strength are critical. According to a report from the Research and Markets, the high-performance thermoplastics market is expected to grow at a CAGR of 10.4% from 2021 to 2026, largely driven by innovations in materials like PEEK.

When comparing PEEK to traditional materials, the mechanical strength and chemical resistance of PEEK are particularly noteworthy. PEEK exhibits a tensile strength over 90 MPa, offering superior mechanical performance in challenging environments. In contrast, traditional materials like nylon and acetal typically provide tensile strengths under 70 MPa, which may limit their application in high-stress environments. Furthermore, PEEK is resistant to hydrolysis and can withstand harsh chemicals, which enhances its longevity and reliability in various industrial applications, as reported by the Global Industry Analysts report on high-performance polymers. This positions PEEK as a leading choice for industries that require materials that not only endure extreme conditions but also contribute to overall system efficiency and reliability.

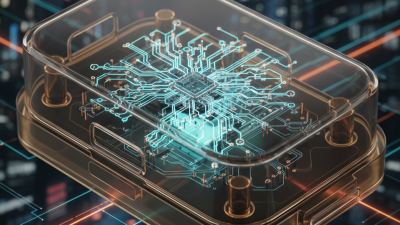

Peek polymer, known for its exceptional performance characteristics, has gained prominence across a multitude of industries. In aerospace, its lightweight nature and high thermal stability make it an ideal choice for components requiring resistance to extreme temperatures and harsh environmental conditions. Engineers rely on Peek for parts such as electrical connectors and battery components, where reliability is essential for safety and performance.

In the medical field, Peek polymer's biocompatibility allows for its use in various applications, including surgical instruments and implantable devices. Its ability to withstand sterilization processes while maintaining structural integrity ensures that it meets stringent health regulations. Furthermore, the automotive industry benefits from Peek's strength and chemical resistance, utilizing it in fuel systems, transmission components, and under-the-hood applications where durability is crucial. Overall, the versatility of Peek allows it to address the rigorous demands of these diverse sectors, signaling its vital role in the future of high-performance materials.

| Industry | Key Applications | Advantages of PEEK | Temperature Resistance | Commercial Examples |

|---|---|---|---|---|

| Aerospace | Insulation components, electronics housing | Lightweight, chemical resistance, high strength | Up to 260°C | Fuel systems, engine covers |

| Medical | Surgical instruments, implants, wearables | Biocompatible, sterilizable, durable | Up to 260°C | Knee and hip implants, dental tools |

| Automotive | Electrical connectors, gaskets, bearings | Self-lubricating, lightweight, heat resistance | Up to 260°C | Gearboxes, engine components |

| Oil & Gas | Sealing solutions, downhole tools | Chemical stability, wear resistance | Up to 260°C | Pumps, valves |

| Electrical | Insulators, circuit boards | High dielectric strength, flame resistant | Up to 260°C | Electrical connectors, transformers |

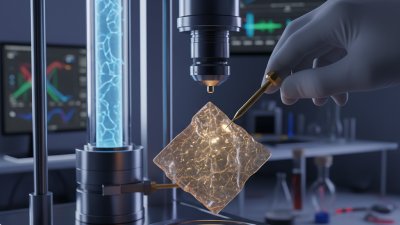

PEEK polymer, known for its exceptional thermal and chemical resistance, is rapidly becoming a leading choice in the realm of high-performance materials. Its manufacturing and processing techniques are crucial for industries that demand rigorous material properties, particularly in aerospace, automotive, and medical sectors. Advanced techniques such as injection molding and additive manufacturing allow for the precise fabrication of PEEK parts, enhancing its performance characteristics. According to a recent industry report, the global PEEK market is projected to reach USD 1.5 billion by 2025, with a CAGR of 8.5%. This growth is fueled by the increasing adoption of, and advancements in, processing technologies.

Tips: When considering PEEK for applications, it is essential to evaluate the specific requirements of your project. For instance, optimizing the injection molding parameters, such as temperature and pressure, can significantly influence the mechanical properties and surface finish. Additionally, utilizing 3D printing techniques with PEEK can reduce waste and allow for the creation of complex geometries that were previously unattainable with traditional methods.

Furthermore, the sustainability of processing methods is gaining importance as organizations strive to minimize their environmental impact. Innovations such as solvent extraction and recycling of PEEK wastes are being explored to create a circular economy within the industry. This not only reduces raw material consumption but also enhances the overall appeal of PEEK polymer as a sustainable high-performance material.

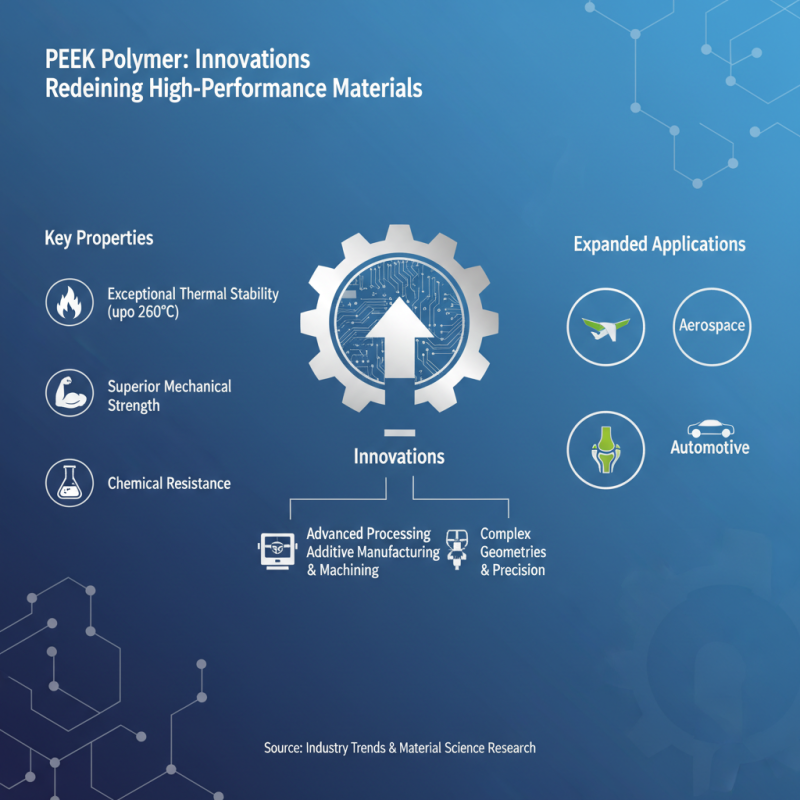

The development of PEEK (polyether ether ketone) polymer is witnessing remarkable trends and innovations that promise to redefine the landscape of high-performance materials. As industries continue to demand materials that can withstand extreme conditions, PEEK stands out due to its exceptional thermal stability, mechanical strength, and chemical resistance. Innovations in processing techniques, such as advancements in additive manufacturing and machining, are enabling the production of PEEK components with greater precision and complex geometries, which expands its application potential beyond traditional uses.

Moreover, ongoing research into modified PEEK formulations is enhancing its properties to meet specific industry requirements, paving the way for its adoption in sectors like aerospace, automotive, and medical. Developments such as incorporating nanomaterials to improve PEEK's toughness further illustrate the innovative spirit driving this sector. These tailored materials not only promise improved performance but also open doors to breakthrough applications where conventional materials may fall short. As the emphasis on sustainability grows, exploring bio-based alternatives in PEEK production could lead to greener options, thus aligning with global trends towards eco-friendly materials.