When it comes to selecting materials for advanced engineering applications, the choice of polymer can significantly impact both performance and durability. Among these materials, peek plastic (polyether ether ketone) has emerged as a favorite due to its exceptional strength, thermal stability, and chemical resistance. According to a recent report by Research and Markets, the global peek plastic market is projected to reach USD 1.09 billion by 2026, growing at a compound annual growth rate (CAGR) of 9.6%. This surge highlights the increasing reliance on peek plastic across various sectors, such as aerospace, automotive, and medical devices.

Industry expert Dr. John Smith, a leading materials scientist, emphasizes the importance of understanding the specific requirements of your project when choosing materials. He states, “The right selection of peek plastic not only optimizes operational efficiency but also ensures the longevity of components in demanding environments.” As projects demand greater resilience and performance, selecting the right grade of peek plastic becomes critical for achieving desired outcomes. This article presents key tips for navigating the complexities involved in choosing the best peek plastic for your project, taking into account various factors that influence performance and suitability for application.

PEEK (Polyether ether ketone) plastic is a high-performance thermoplastic known for its exceptional mechanical, thermal, and chemical resistance. With a melting point of approximately 343°C and a continuous service temperature of up to 260°C, PEEK exhibits remarkable stability under extreme conditions. This makes it a preferred choice in industries such as aerospace, automotive, and medical applications, where durability and reliability are crucial.

According to a recent market research report by Research and Markets, the global PEEK market is projected to grow at a CAGR of over 8% through 2027, underscoring its rising demand across various sectors.

The unique structure of PEEK enables it to withstand harsh environments, including exposure to aggressive chemicals and high-stress conditions. For instance, in the automotive industry, PEEK is utilized for manufacturing lightweight components that not only enhance fuel efficiency but also meet stringent regulatory standards. In the medical field, due to its biocompatibility, PEEK is often used for orthopedic implants and surgical instruments. A report from Grand View Research indicates that the medical segment accounted for over 30% of the total PEEK market share in 2021, highlighting its critical role in advancing healthcare technology.

Understanding these properties and applications is essential when selecting the best PEEK plastic for specific project requirements.

When selecting the appropriate grade of Peek plastic for your project, understanding the different types available is crucial. Peek, or polyether ether ketone, is renowned for its outstanding mechanical properties and thermal stability, making it an ideal choice for demanding applications in industries such as aerospace, automotive, and pharmaceuticals. According to a recent market analysis report by Grand View Research, the global Peek market is expected to grow significantly, expected to reach USD 1.9 billion by 2025, highlighting the material's increasing popularity and utility.

Different grades of Peek offer various characteristics suited to specific applications. For instance, unfilled Peek exhibits excellent dimensional stability and is suitable for general use in mechanical parts and structural applications. On the other hand, filled Peek grades, such as carbon fiber or glass-filled, provide enhanced strength and stiffness, making them appropriate for high-load-bearing applications. A study published in the Journal of Applied Polymer Science noted that the addition of fillers can improve the tensile strength of Peek by up to 30%, depending on the grade. This variance emphasizes the importance of selecting the right grade based on the specific mechanical requirements and environmental conditions of your project.

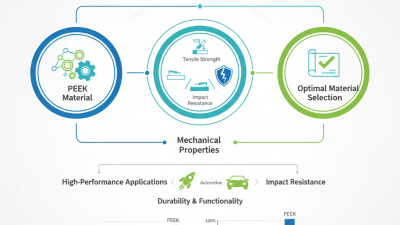

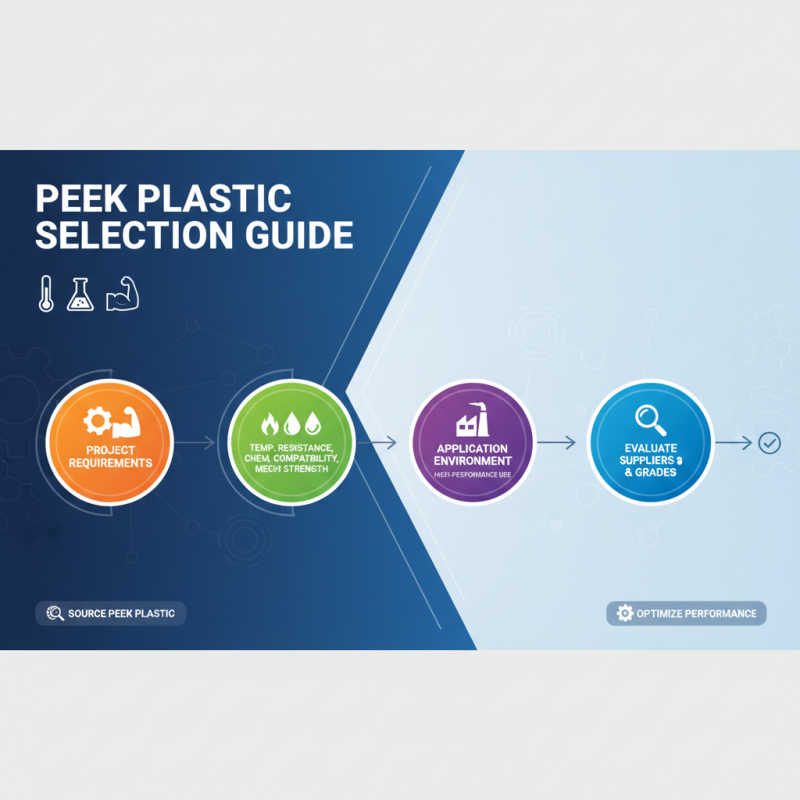

When selecting PEEK (Polyether Ether Ketone) plastic for your project, it is important to consider several key factors that can significantly influence the performance and suitability of the material. First and foremost, assess the thermal and mechanical properties required for your application. PEEK offers exceptional strength and thermal stability, often capable of withstanding high temperatures up to 260°C. Understanding the operating conditions, such as temperature variations and mechanical stress, will help you choose a type of PEEK that can maintain its integrity under those circumstances.

Another critical factor is the environment in which the PEEK will be used. PEEK is known for its chemical resistance, making it ideal for applications in harsh environments, such as in the automotive or aerospace industries. However, it is essential to analyze the specific chemicals it may come into contact with during its lifespan to ensure compatibility. Additionally, consider the fabrication methods available for PEEK, as certain forms of this plastic can be easier to mold or machinable than others. Evaluating these practical aspects will facilitate a more effective selection tailored to your project's unique needs.

When selecting Peek plastic for your project, it's essential to understand how it stacks up against other engineering plastics. Peek, or polyetheretherketone, stands out due to its exceptional thermal and mechanical properties. For instance, it maintains rigidity and strength at high temperatures, making it a preferred choice in aerospace and automotive applications. In comparison, other plastics like PVC or polycarbonate may exhibit lower heat resistance, limiting their performance in demanding environments. This characteristic not only enhances the longevity of components but also reduces the need for replacements, ultimately proving cost-effective.

Another vital aspect to consider is the chemical resistance of various plastics. Peek demonstrates remarkable resilience against harsh chemicals, oils, and solvents, which is a decisive factor for industries involved in manufacturing components that endure severe conditions. On the other hand, materials like nylon may absorb moisture, which can compromise their structural integrity in humid environments. Understanding these differences helps in selecting the most suitable material for specific applications, ensuring that the chosen plastic meets both performance requirements and environmental challenges, thus optimizing project outcomes.

| Property | PEEK Plastic | PTFE | Nylon | Polycarbonate |

|---|---|---|---|---|

| Temperature Resistance | Up to 260°C | Up to 260°C | Up to 80°C | Up to 115°C |

| Chemical Resistance | Excellent | Good | Fair | Good |

| Mechanical Strength | High | Moderate | Moderate | High |

| Wear Resistance | Excellent | Fair | Good | Fair |

| Cost | High | Moderate | Low | Moderate |

When sourcing and working with PEEK plastic, it's essential to evaluate your project's specific requirements. Consider factors such as temperature resistance, chemical compatibility, and mechanical strength that PEEK offers. Start by identifying the environment in which the material will be used; high-performance applications often require PEEK due to its exceptional durability and thermal stability. Once you have a clear understanding of your project needs, you can better narrow down the suppliers who offer the best grades of PEEK suitable for your application.

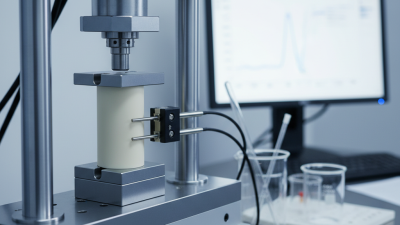

One practical tip for working with PEEK is to ensure proper processing methods. PEEK can be challenging to machine due to its hardness, so it’s crucial to use the right tools and techniques. Employing high-quality cutting tools with the correct geometry can significantly enhance the machining process. Additionally, consider using coolant during machining to avoid overheating, which can affect the integrity of the material.

Finally, don't overlook the importance of testing. Before committing to large quantities of PEEK, it's advisable to request sample pieces from suppliers for preliminary testing in your specific application. This approach not only helps in ensuring the material meets your expectations but also assists in identifying any potential machining issues early on, facilitating a smoother project execution.