Polyetheretherketone (PEEK) has emerged as a game-changing thermoplastic in various industries, thanks to its remarkable properties such as high-temperature resistance, mechanical strength, and chemical stability. As we look ahead to 2025, the applications of PEEK are expected to expand significantly, influenced by advancements in manufacturing technologies and increasing demand for innovative materials in sectors like aerospace, automotive, and medical. Industry expert Dr. Emily Huang, a leading researcher in high-performance polymers, emphasizes the future potential of PEEK by stating, "The versatility of polyetheretherketone is only beginning to be recognized; its unique characteristics will redefine material applications across diverse sectors."

As companies strive to meet stringent regulations and sustainability goals, the ability of polyetheretherketone to withstand harsh environments while still being recyclable adds immense value to its implementation. Experts predict that by 2025, we will see a surge in PEEK's utilization in high-stress applications, enabling industries to create lighter, more efficient, and environmentally friendly solutions. In this rapidly evolving landscape, understanding the trends and insights surrounding polyetheretherketone will be crucial for stakeholders aiming to harness its full potential and drive innovation forward.

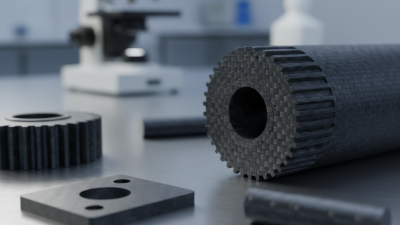

Polyetheretherketone (PEEK) is a high-performance thermoplastic that has gained significant traction across various industries due to its exceptional mechanical, thermal, and chemical resistance properties. In 2025, the industrial importance of PEEK continues to rise, particularly in sectors such as aerospace, automotive, medical, and electronics. Its lightweight nature and ability to perform under extreme conditions make it an ideal material for components that require durability and reliability, which is crucial for enhancing the overall performance of modern applications.

Tips: When considering the use of PEEK in your projects, evaluate the specific requirements such as temperature resistance, mechanical loading, and chemical exposure to ensure you select the right grade of PEEK for your application. Additionally, understanding the manufacturing processes that best suit PEEK, such as injection molding and extrusion, can further enhance productivity and end-product quality.

As industries evolve, so do the applications of PEEK. Emerging trends indicate an increasing focus on sustainable manufacturing practices, where PEEK’s recyclability can play an important role. Integrating PEEK into supply chains not only enhances product performance but also contributes to environmental goals by reducing waste and promoting resource efficiency. Embracing this innovative material can position companies at the forefront of industry advancements as they address the growing demand for high-performing, sustainable solutions.

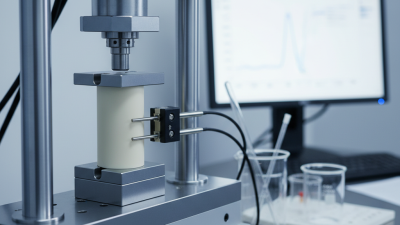

Polyetheretherketone (PEEK) continues to revolutionize manufacturing due to its remarkable properties and benefits. Known for its high-temperature resistance, excellent chemical and wear resistance, and superior mechanical strength, PEEK is increasingly favored across various industries, including aerospace, automotive, and medical. According to a recent market report by Grand View Research, the global PEEK market size was valued at approximately $500 million in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 12% from 2022 to 2030. This robust growth can be attributed to its unique characteristics, making it an ideal material for applications requiring durability and reliability under extreme conditions.

The lightweight nature of PEEK, combined with its ability to withstand harsh environments, has made it a game-changer in sectors prioritizing performance without compromising weight. For instance, in aerospace applications, PEEK's thermal stability allows it to be used in components exposed to high temperatures, significantly improving the efficiency of aircraft systems. Additionally, the material's biocompatibility makes it suitable for medical implants and devices, reinforcing the trend towards using advanced polymers in critical applications. A report from Research and Markets highlights that the demand for PEEK in the medical sector is anticipated to grow substantially due to its favorable properties, with the segment expected to account for over 25% of the market share by 2025. These insights underline the transformative role of PEEK in modern manufacturing, emphasizing its importance in driving innovation and efficiency across diverse industries.

This bar chart illustrates the projected applications of Polyetheretherketone (PEEK) in various industries by 2025, showcasing its significance in manufacturing.

Polyetheretherketone (PEEK) is gaining traction across various industries due to its exceptional mechanical properties and resistance to extreme environments. In 2025, the aerospace sector is projected to be one of the dominant fields utilizing PEEK, with a significant rise in its application for lightweight components that can withstand high temperatures and abrasive conditions. Reports project that the demand for high-performance thermoplastics in aerospace could exceed $1.5 billion by 2025, where PEEK will play a pivotal role in reducing weight without compromising strength.

Additionally, the medical industry is set to embrace PEEK applications extensively in advanced implants and surgical instruments. The biocompatibility and sterilization capabilities of PEEK render it ideal for such use cases. According to industry forecasts, the medical thermoplastics market, including PEEK, is expected to grow at a CAGR of 8.5% between 2023 and 2025, reflecting the increasing shift towards more durable and efficient surgical materials. With a focus on developing innovative solutions, manufacturers are exploring PEEK's use in areas such as dental applications and orthopedic devices, enhancing patient outcomes through more reliable and longer-lasting products.

| Industry | Application | Key Benefits | Projected Growth Rate (2025) |

|---|---|---|---|

| Aerospace | Structural Components | High strength-to-weight ratio, heat resistance | 5% CAGR |

| Automotive | Fuel System Components | Chemical resistance, durability | 7% CAGR |

| Medical | Surgical Instruments | Biocompatibility, sterilizability | 6% CAGR |

| Electronics | Insulators and Connectors | Electrical insulation, thermal stability | 4% CAGR |

| Oil & Gas | Sealing Components | Resistance to harsh chemicals, high temperatures | 8% CAGR |

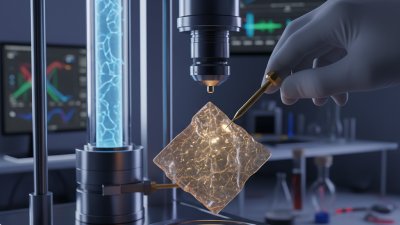

In recent years, polyetheretherketone (PEEK) has emerged as a material of choice across various industries due to its excellent mechanical properties, thermal stability, and chemical resistance. As technological advancements continue, several innovative applications of PEEK are surfacing. One notable trend is its increasing use in the aerospace sector, where lightweight materials are essential for improving fuel efficiency. Advanced processing techniques, such as additive manufacturing, are enabling the customization of PEEK components, allowing for more intricate designs while maintaining structural integrity.

Another significant trend is the growing adoption of PEEK in the medical field. The development of bio-compatible grades of PEEK is revolutionizing surgical implants and dental devices, making them more durable and resistant to wear. Innovations in surface modification technologies are enhancing the integration of PEEK implants with human tissue, thereby elevating patient outcomes. Moreover, as more research is conducted, the potential for PEEK in regenerative medicine and drug delivery systems is becoming a focal point, indicating a promising trajectory for future applications. These trends highlight the versatile nature of PEEK and underscore its role as a front-runner in materials science innovation.

The demand for polyetheretherketone (PEEK) is anticipated to experience significant growth in the coming years, driven by its unique properties and applications across multiple industries. As a high-performance thermoplastic, PEEK provides excellent mechanical strength, chemical resistance, and thermal stability, making it an ideal choice for sectors such as aerospace, automotive, medical, and electronics. Industry insights suggest that advancements in manufacturing processes and increased awareness of PEEK’s benefits will further contribute to this upward trajectory.

Market projections indicate that the ongoing trend towards lightweight and durable materials will propel PEEK's adoption in high-stress environments, particularly in the aerospace and automotive industries, where fuel efficiency and performance are paramount. Additionally, the medical sector's rising demand for precision components and implants that meet stringent regulatory standards is set to amplify PEEK's market presence. Emerging applications, such as in 3D printing and advanced manufacturing techniques, are also expected to open new avenues for PEEK usage, reinforcing its position as a vital material in future innovations. These factors collectively underscore a robust outlook for PEEK demand and market growth, positioning it as a critical player in upcoming technological advancements.